How to Properly Engineer Efficiency at Your Aggregates Site

February 2, 2024Choosing the Right Conveyor Sidewall Pocket Size for Improved Performance

February 7, 2024Concerns regarding environmental preservation and sustainability are on the rise. One industry that is actively working towards positive change in this realm is recycling. Recycling is an industry with the mission of reducing waste, often with initiatives implemented to ensure no recycling ends up in landfills.

In order to perform these operations efficiently, facilities must have specialized conveying equipment. One piece of equipment that has been proven to be a game changer in this industry is magnetic separator belts. These belts improve driving efficiency. Recycling plants need to make sure that their facilities have this equipment operating at peak performance in order to maximize the recovery of ferrous metals.

Revolutionary Belting

Magnetic separator belts have truly revolutionized how waste materials are processed and recycled, significantly contributing to this industry’s waste reduction and resource conservation mission. These belts remove ferrous metals from the rest of the recyclables being processed, providing enhanced sorting efficiency, increased safety, improved end-product quality, and positive environmental impacts.

Enhanced Sorting Efficiency

Magnetic separator belts are designed to separate and extract ferromagnetic materials from the rest of the recycling materials. These ferrous metals, like iron and steel, are commonly found in scrap metal, electronic waste, and construction debris. Magnetic separator belts are able to easily extract these unwanted metals from waste flow, simplifying the sorting process at recycling facilities.

Increased Safety

Removing hazardous metals from the recycling stream allows for a safer working environment. Recycling employees are putting themselves at risk when they try to handle potentially shart or contaminated metal during the waste flow. Utilizing magnetic separators can help to mitigate these risks, improving workplace safety overall.

Reduced Equipment Damage

Another way that magnetic separator belts can help in recycling is to help prevent system damage by removing unwanted metals. Ferrous metals are known to wreak havoc on recycling processing machinery. Crushers, grinders, and other equipment can suffer intense damage from these metals, meaning recycling facilities have increased maintenance costs and unnecessary downtime. Magnetic separators can save time and money for businesses by mitigating these concerns.

Improved End-Product Quality

If ferrous contaminants manage to slip through the recycling process, they can severely impact the quality of the final recycled product, including reduced strength and durability as a result of metal impurities. Thanks to magnetic separator belts, the recycling process can create more pure end products, increasing demand and profitability.

Environmental Benefits

The recycling industry is committed to reducing raw material demand and lowering overall energy consumption. Magnetic separator belts assist in this by increasing the recycling yield and purity of wase flow. This leads to a number of benefits, including reduced environmental footprint, additional extraction and manufacturing of new materials, and a more sustainable future overall.

Contact Our Team of Experts Today

Our Motion Conveyance Solutions team understands the challenges presented in the recycling industry and will work to provide you with the best solution for your application. Reach out to our team today to learn more.

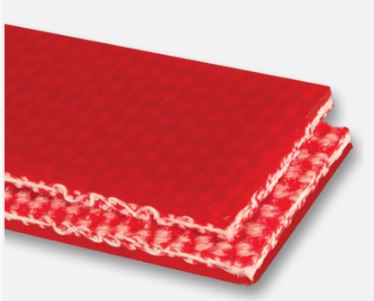

Interwoven 90# Polyester Red Urethane Cover X Brushed (Novex)

Interwoven 90# Polyester Red Urethane Cover X Brushed (Novex)

This versatile spec with urethane cover is used widely in recycling due to its resistance to cutting, gouging and chemicals. Learn more.

Interwoven 120# Polyester Red Urethane Cover X Brushed (All Urethane)

Interwoven 120# Polyester Red Urethane Cover X Brushed (All Urethane)

This all urethane belt is a standard in many automotive stamping operations. Also highly recommended in many recycling plants and other abrasive jobs. Learn more.

Interwoven 200# Polyester Red Urethane Cover X Brushed

Interwoven 200# Polyester Red Urethane Cover X Brushed

This belt is the standard in many automotive stamping operations. Also highly recommended in many recycling plants and other abrasive jobs. Learn more.