The Importance of Appropriate Safety Precautions with Anhydrous Ammonia Hose

December 21, 2023Supporting Cleanup Efforts When Flooding Hits: The Power of Suction Hoses and Discharge Hoses for Pumps

February 12, 2024More often than not, your hoses take a beating in your day-to-day operations. Dragging a new hose on abrasive flooring, dropping it on hard surfaces, scratching or nicking it on sharp objects, or tangling it into knots could quickly end its life. Rather than purchasing a new hose more often than necessary, it is essential to invest in hose bumpers.

Hose bumpers are small, circular objects that fit on the end of your hoses to protect them from normal wear and tear and particularly harsh environments. Various hose bumpers can easily fit any hose in your facility and save you money and time in the long run.

Hoses are constantly being connected and disconnected during a typical shift. Hose bumpers can decrease the risk of thread damage or product contamination by protecting the hose end. But that is not the only benefit of using hose bumpers.

Protection and Safety

Hoses are constantly moving around the facility to transfer materials daily. Hose bumpers protect your hoses from abrasion and wear and tear from constant rubbing against other materials. They can also absorb shock when being dragged across surfaces.

Hose bumpers can prevent injuries caused by rogue hoses. They help aid users in controlling the movement of the hose, making it easier to avoid injuries.

Stability

In high-pressure situations, the last thing you need is faulty equipment. Hose bumpers can benefit you by keeping your operations running smoothly. Bumpers protect the outside and connections of your hoses, allowing your facility to maintain operations at all times.

Noise Reduction

Processing can be noisy. The loudness can impair your and your employees' hearing while risking miscommunication due to the noise. Hose bumpers allow for a quieter work environment, especially when your hoses are dropped or dragged throughout the day.

Cost-Effectiveness

Purchasing new hoses to replace broken ones can quickly get expensive. By implementing hose bumpers, you get peace of mind from their ability to resist damage from harsh environments. They are crucial to protecting your equipment and saving you unnecessary costs.

Ease of Maintenance and Versatility

Generally, hose bumpers are easy to install and replace, reducing maintenance time and keeping your hoses fit for as long as possible. Hose bumpers come in several sizes, types, and materials. Metal and silicon are the most popular materials used for hose bumpers.

During cleanup, hose bumpers enhance the cleanup or washdown process. They elevate the hose from the floor, preventing a dam effect during washdowns. This allows water to flow directly to the drains, easing the process altogether.

Kinking and Tangling Prevention

Hose bumpers keep hoses rigid, providing easy transportation of materials and keeping the flow moving.

Reach Out Today

Hose bumpers are critical in any production line with moving products. They make transporting materials faster and easier, save your facility money, keep your employees safe, and protect your equipment to extend their life.

Contact a Motion Conveyance Solutions rep today and learn which hose bumper would work best for you and your facility.

Related Products

![]()

BLAUDIECK® Fitting System

![]()

COLLECTOR®

![]()

BLAUDIECK® LGDU

![]()

COLLECTOR®

FLEX

![]()

BLAUDIECK® LGDSU

![]()

CONTI® Blue Steam

![]()

CONTI® Cleanjet - FDA

![]()

PAGUCLAMP® Fitting System

![]()

Purpurschlange® Plus Conductive

![]()

CONTI® Food & Drink Flex UPE

![]()

PAGUFIX® Fitting System

![]()

Rubber Protection Ring

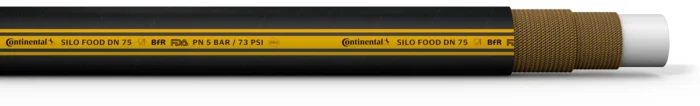

CONTI® Silo Food

CONTI® Silo Food

![]()

Purpurschlange®